How Do They Form the Metal for Making Cars?

Sep 26, 2016

As an Amazon Associate, Modded gets commissions for purchases made through links in this post.

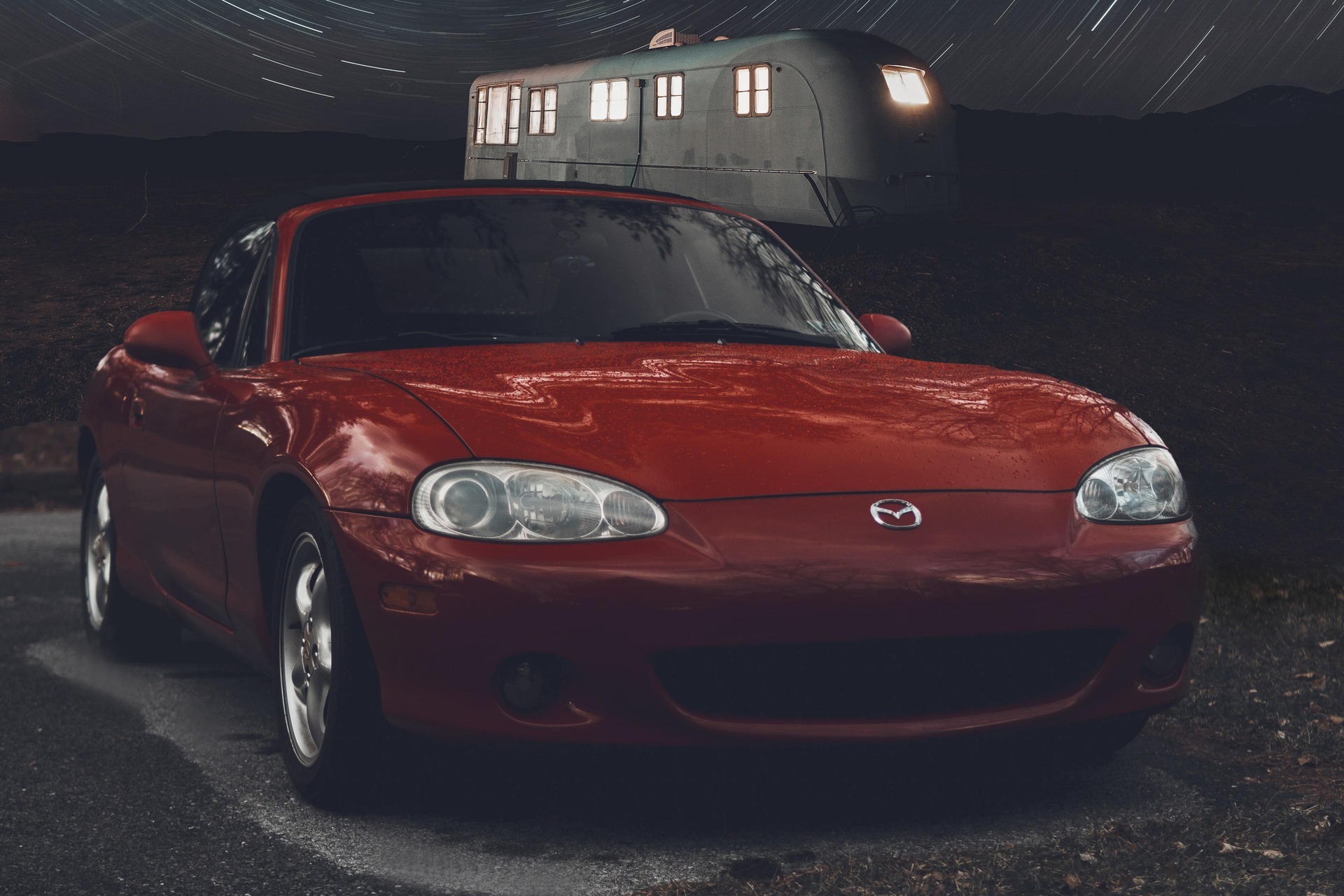

There are thousands of cars driving on roads around the world every single day, but have you ever looked at the cars next to you on the road or in the parking lot and wondered how they make the metal parts for them? If you’ve ever been curious about how your car was formed, or our question has piqued your curiosity, then read on.

You’re Hot, Then You’re Cold

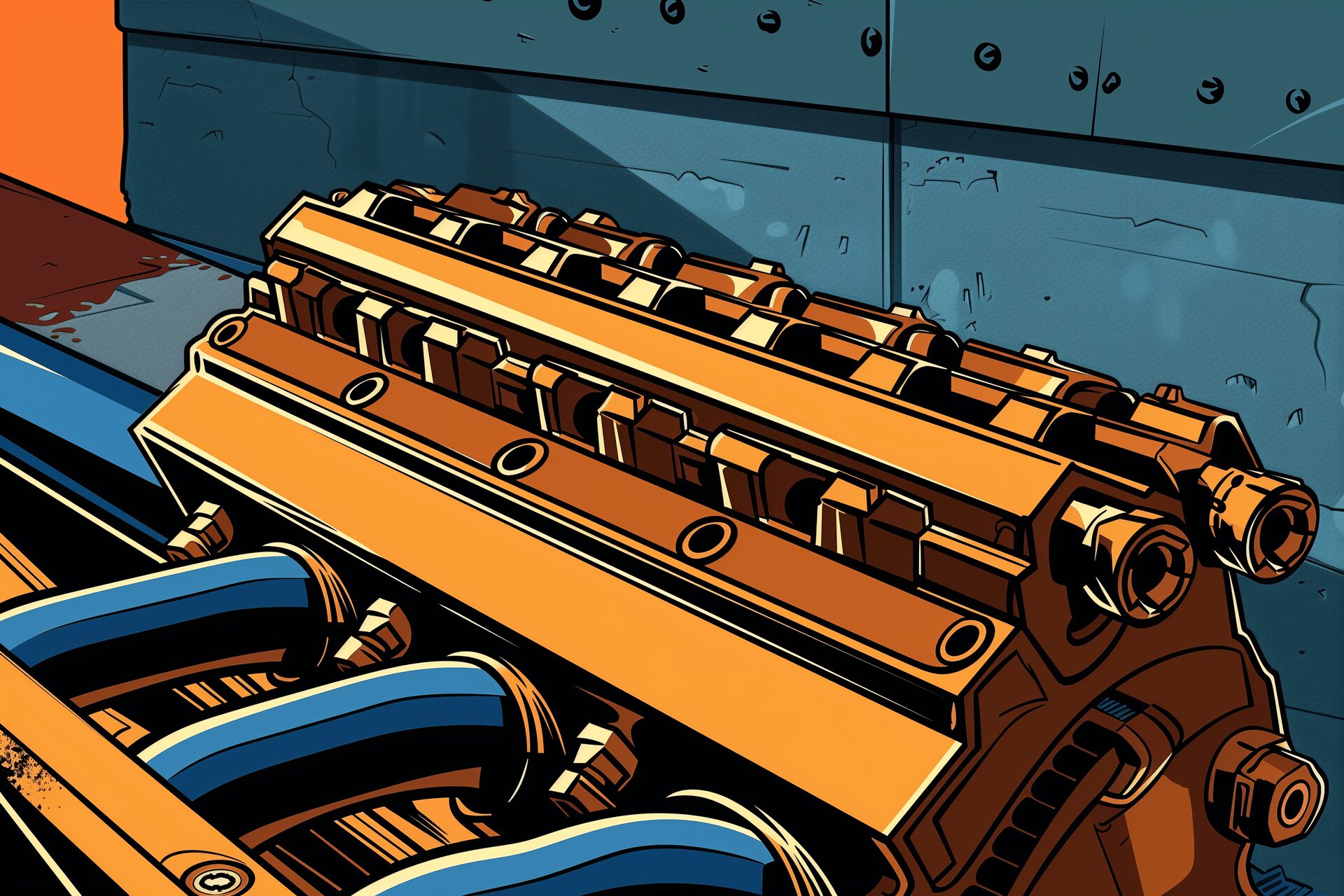

The concept of metal forging usually brings to mind steel mills with their enormous crucibles full of molten metal, which reaches astonishing temperatures of 2500F or more. While that may have been the case in the past, most metal automotive parts are now made using a method called cold forging.

Instead of relying on the melting point of the iron or steel being used in metal car components, cold forging allows the metal to be forged at temperatures as low as 70F. That’s low enough that you could easily pick up a recently forged piece with your bare hands immediately after it is formed.

Perks of Being Cold

What are the benefits of cold forging when compared to traditional forging techniques? These include:

- Plastic deformation: While you’re working with metal instead of plastic, cold forging allows the metal to take on one of the most unique characteristics of plastic — the ability to take on any shape. That allows the metal to be formed into any shape you possibly need.

- Precious metals: Most softer metals, like gold and silver, are hard to forge traditionally due to the elasticity of the metal itself. It tends to get “gummy,” making it hard to form. Cold forming allows these metals to be formed into any shape without becoming too gummy to work with.

- Accuracy: Cold forging allows the parts to be much more accurate, requiring less polishing or modification after the part is cool enough to work with.

- Almost no waste: Traditional forging techniques create product waste — scraps and pieces of leftover material that cannot be used for their intended purpose. Cold forging, on the other hand, creates almost no waste, using nearly 100 percent of the metals.

Types of Cold Forging

Cold forging for car parts is primarily done using 1 of 4 techniques:

- Forward extrusion: Also called impact extrusion. A slug of metal is pressed through a die using tremendous pressure, forcing the metal into the desired shape.

- Backward extrusion: Instead of pressing the metal through a die, the metal is pushed backward, hence its name. This is perfect for creating holes or cup shapes, among other things.

- Combined extrusion: If necessary, the two previously mentioned forms of extrusion can be combined to create unique and fantastic pieces.

- Upsetting: This technique forces metal out of the die and can also be used to flatten metal.

Each of these types of techniques has one thing in common — pressure. Cold forging is most commonly achieved by putting the target material under enormous amounts of pressure to force it to take the desired shape without having to bring the metal to its melting point.

Embrace the Process of Making Cars

If you’ve ever wondered how your favorite car was made, you have your answer! It’s cold-forged metals, or metals that are pressed into a shape rather than melted and cast into the forms of the pieces needed. This also enables cars to be made much faster and easier than ever before.